|

Are you still looking for a CNC machining manufacturer factory or are you confused about CNC related technology Here we provide global CNC machining and manufacturing factories, as well as enterprise related technologies! Because we are a CNC free and open platform!

Please request the CNC machining supplier you want to process materials such as metal (aluminum, steel, titanium, etc.), plastic, wood, etc.

Part complexity: Whether multi axis machining (3-axis, 4-axis, 5-axis), high precision (± 0.01mm), and surface treatment (anodizing, electroplating, etc.) are required.

Order quantity: small batch prototype or large-scale production.

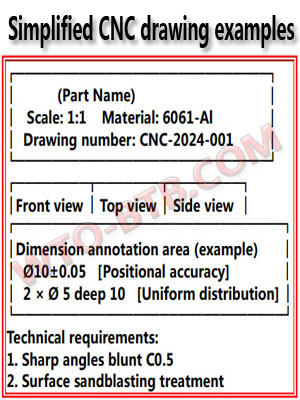

File preparation: Provide complete CAD drawings (such as STEP, IGES formats) or 3D models (such as STL).

This way, the company will solve the relevant information for you faster!

|

|

About CNC  CNC (Computer Numerical Control) is a technology that uses computer programs to control machine tools for automated machining. It combines computers with mechanical tools to achieve high-precision and high-efficiency machining processes.

CNC (Computer Numerical Control) is a technology that uses computer programs to control machine tools for automated machining. It combines computers with mechanical tools to achieve high-precision and high-efficiency machining processes. The core characteristics of CNC 1.Automated control: Through pre written programs, computers control machine tools to execute machining instructions, reducing human intervention. 2.High precision and high efficiency: CNC technology can achieve precise machining of complex parts while improving production efficiency. 3.Widely used: CNC machine tools are suitable for processing various parts, including shafts, disks, and complex surfaces. The working principle of CNC 1.The CNC system consists of the machine tool body, CNC system, drive device, and auxiliary device. Its workflow includes: 2.Program input: Input the numerical control program into the computer. 3.Decoding and operation: Computers decode and perform logical operations on programs to generate control instructions. 4.Execution of machining: The driving device controls the movement of the machine tool according to instructions to complete the machining task. Application Fields of CNC CNC technology is widely used in fields such as mold manufacturing, aerospace, and automotive manufacturing, especially in the processing of complex, precision, and small batch parts, where it has significant advantages. In short, CNC is an indispensable technology in modern manufacturing, representing the development direction of machine tool control technology. |

| Latest supply | Global sourcing | Latest exhibition information |

|

|

|